An innovative Process

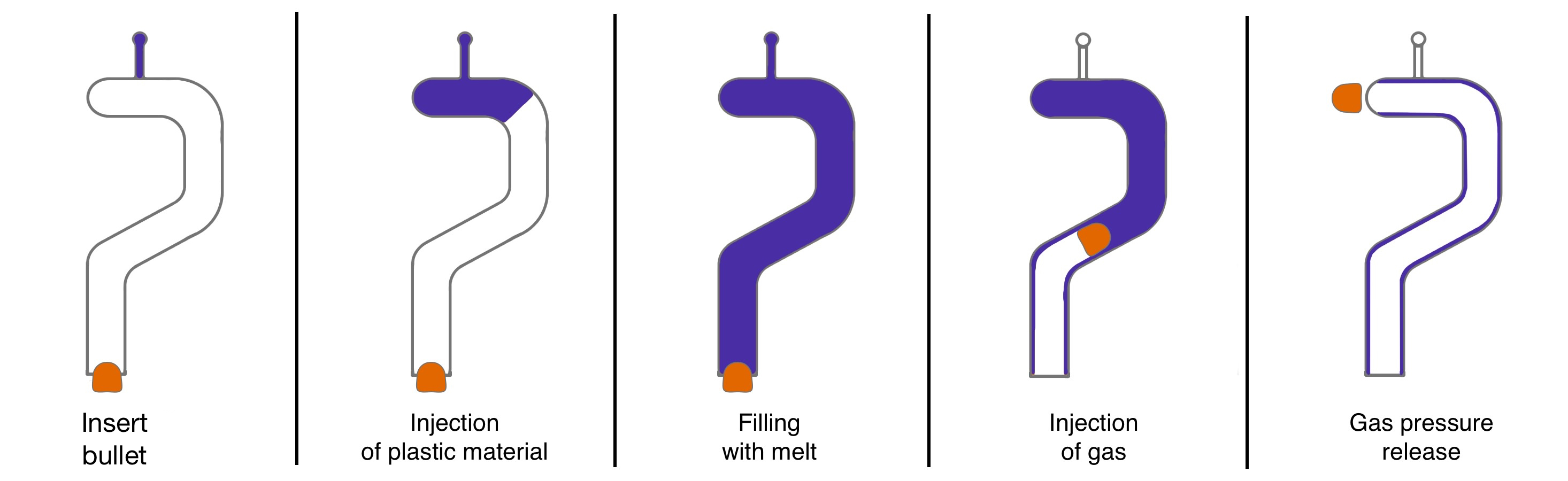

The need to produce pipes with good dimensional constancy and smooth internal surface has made the Projectile Injection Technology a valid alternative.

With this technology it is possible to produce in a single part a tube with bends and equipped with variously shaped attachment points.

With this technology it is possible to produce in a single part a tube with bends and equipped with variously shaped attachment points.